case study

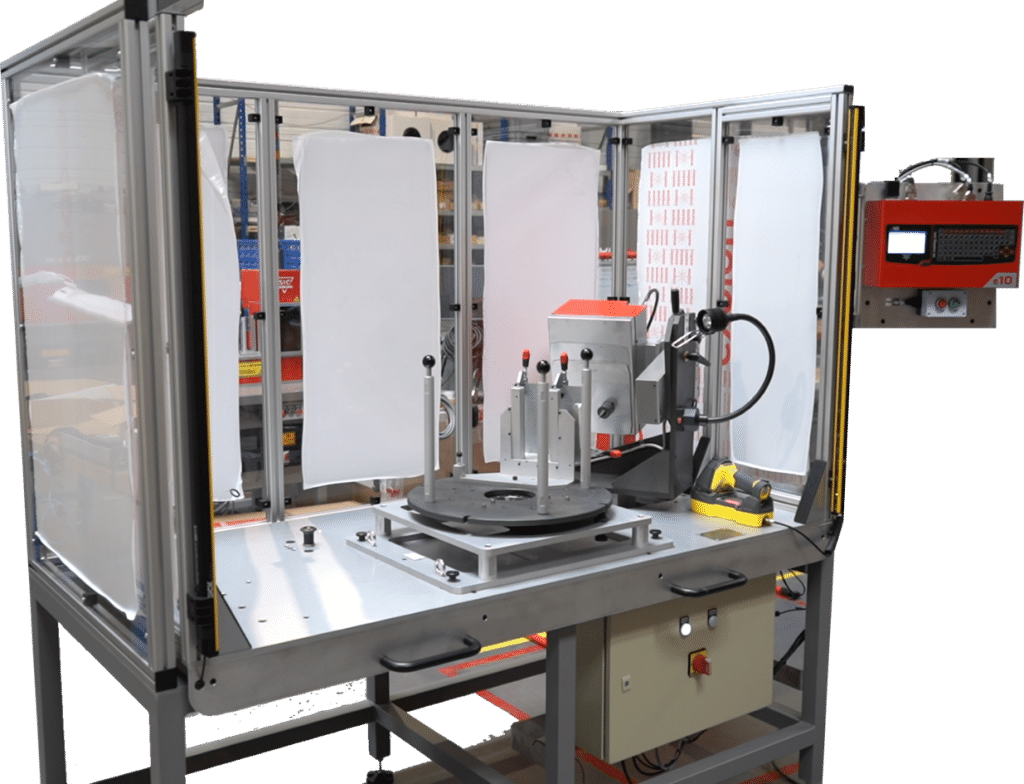

Increasing the roughness of a surface using a laser to counteract the loosening of bolts

An international manufacturer of battery compartments for electric vehicles (EV) wanted to prevent mounting bolts working loose as the result of vehicle vibration.

The manufacturer wanted to intentionally damage the surface around the mounting holes and to make it rough.