case study

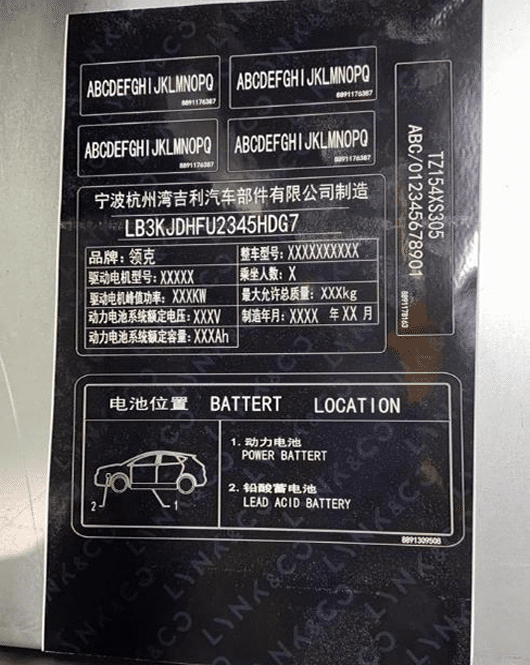

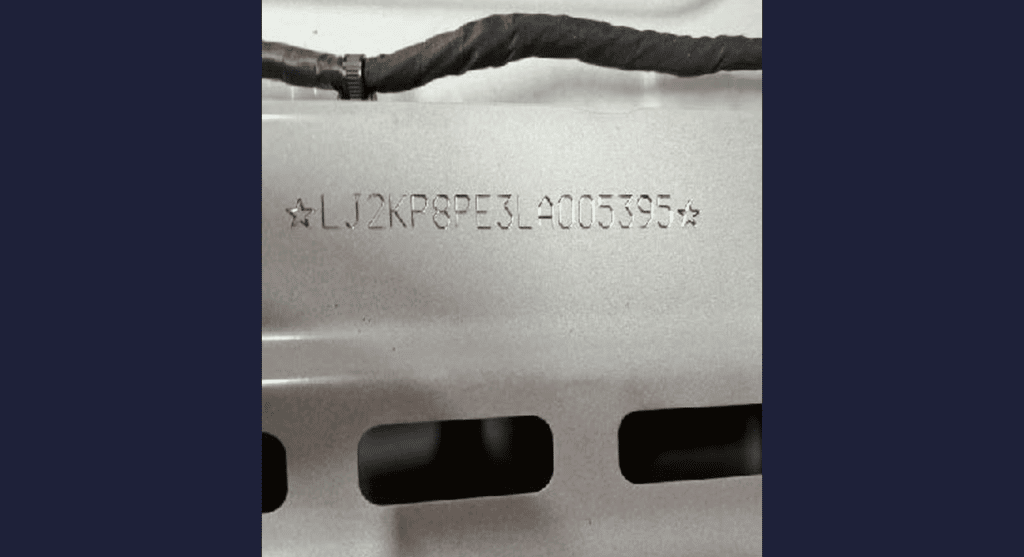

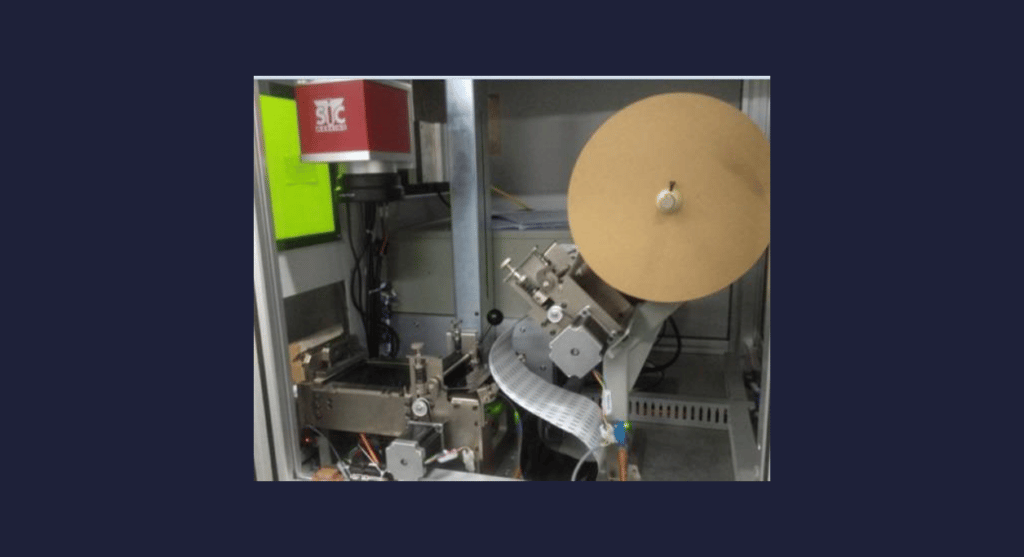

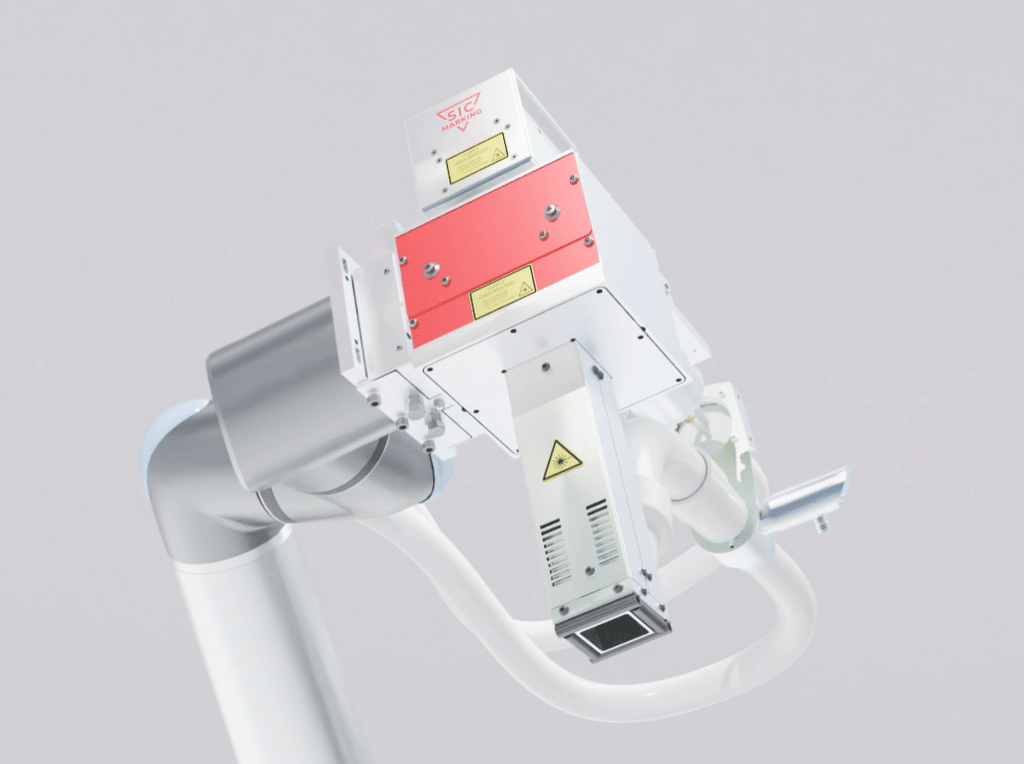

VIN scribe marking and laser marking of the associated plastic labels

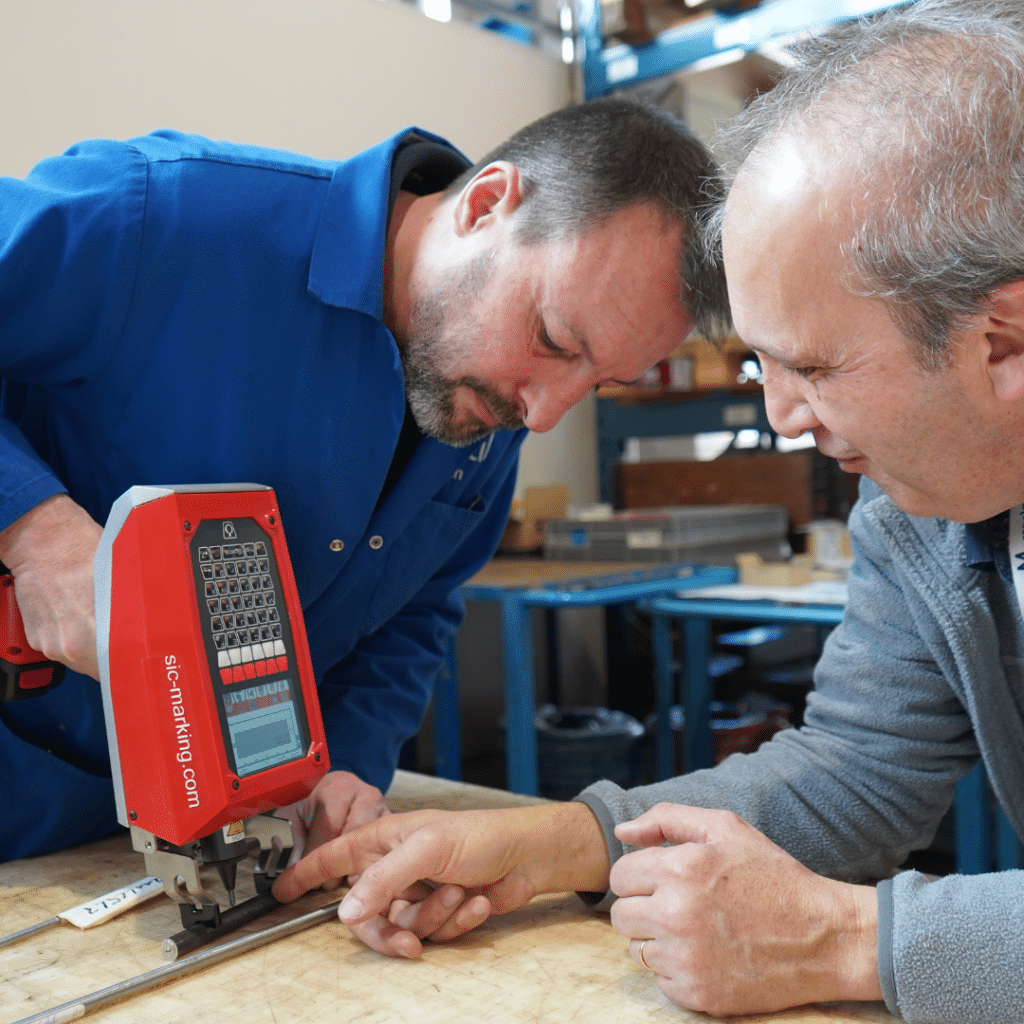

All motor vehicles have a VIN number (Vehicle Identification Number), which must be deeply engraved on their chassis.

SIC Marking is a global VIN scribe marking specialist and offers suitable solutions, using different technologies, to meet this need by adapting to each manufacturer’s specific requirements.

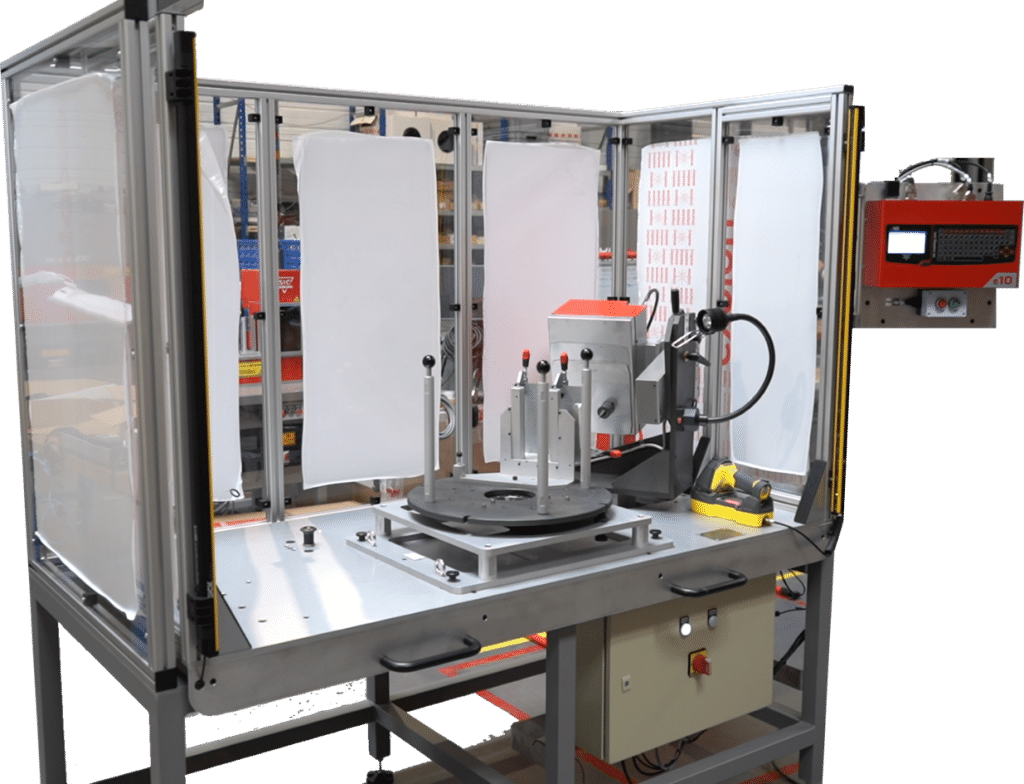

Therefore, the client asked us to supply them with a machine that could engrave the VIN number on the chassis, as well as a machine enabling the VISIVIN adhesive label to be marked.