×

case study

Marking carbon fibre is often a challenging task for manufacturers working within the Aerospace and Motorsport industries.

The need for component traceability within these sectors is critical for ensuring the safety, reliability and quality of components, supporting regulatory compliance and enhancing collaboration across the supply chain.

Traditional mechanical methods such as CNC Machining or Engraving can cause splintering in the material and also does not provide any contrast so the mark can be difficult to see. On top of this, it can be quite a lengthy process as often multiple passes are required to remove a small amount of material each time.

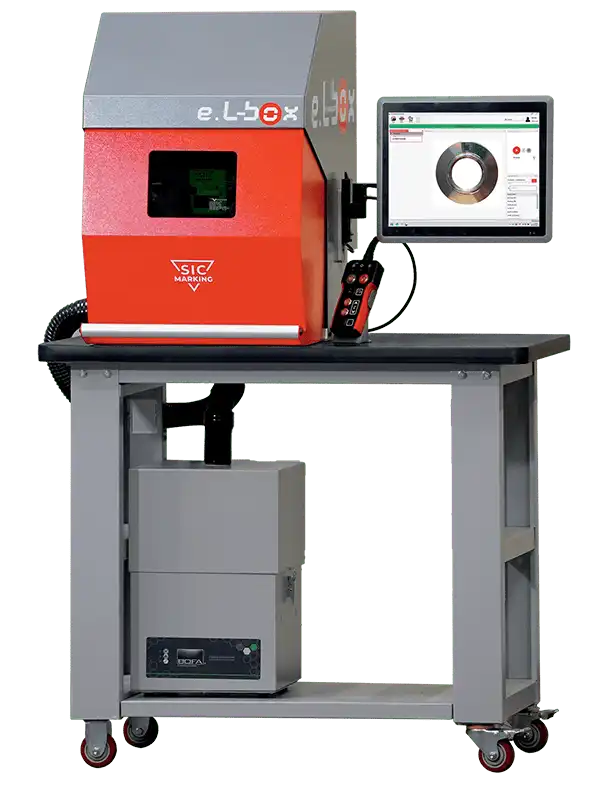

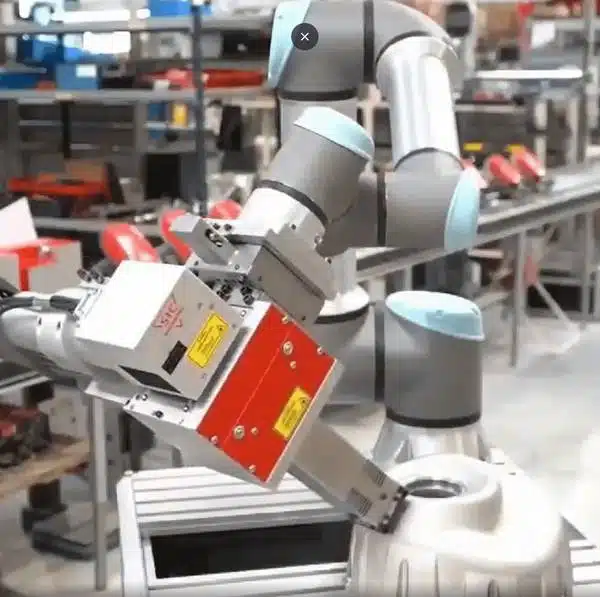

At SIC Marking we’ve developed a specific method and parameter set for our i104 HD Laser that is both quick and provides a good quality of mark that can then be filled with a paint or wax to provide a high level of contrast with minimal heat affected zone around the marking.

The reason we use the i104 HD is that we have the ability to adjust the pulse width of the laser which is something most manufacturers cannot do with their standard 1064nm Fibre Laser.

By being able to adjust and fine tune the pulse width, we can also control the temperature that’s created from the marking process which results in minimal heat damage to the resin layer.

Previous applications where our i104 HD laser has been used include: VIN Marking carbon fibre automotive chassis, serialisation of interior trim components and 2D Datamatrix marking onto Aerospace components.

Our product reference

Take a look at other case studies

Industry

Materials

Technologies

Equipment type

Would you like to know more?

Contact us!