×

case study

Laser marking metal is often referred to as laser etching or laser engraving but frequently all of these mean the same thing. There are a wide range of different laser types available on the market and each of which is suited for certain applications. For laser marking metal components, the most commonly used laser type is Fibre at 1064nm.

1. What It Is

Fibre laser marking uses a laser beam generated by a fibre-optic cable to permanently mark or engrave metal surfaces. It is typically used for traceability, branding, or decorative purposes.

2. How It Works:

The laser beam is directed at the metal surface.

The energy alters the surface by ablation, annealing, or engraving, depending on settings and metal type.

Marks can include serial numbers, barcodes, logos, QR codes, etc.

3. Suitable Metals:

The materials commonly used in Fibre laser marking applications are : Stainless steel, Aluminum (coated and uncoated), Brass, Copper, Titanium, Tool steels, Anodised aluminum, Inconel as well as certain plastics such as ABS and Peak among others.

4. Key Benefits:

High precision and resolution

Non-contact process (no tool wear)

Permanent markings, high-contrast markings

Low maintenance and long laser life (~100,000 hrs)

Fast marking speeds – ideal for industrial production

Etching: Slight material removal for shallow marks.

Engraving: Deeper cuts into the surface.

Annealing: Heat-induced colour change (mainly on stainless steel) with little to material removal.

Black marking: High-contrast marks, especially on anodized or coated surfaces.

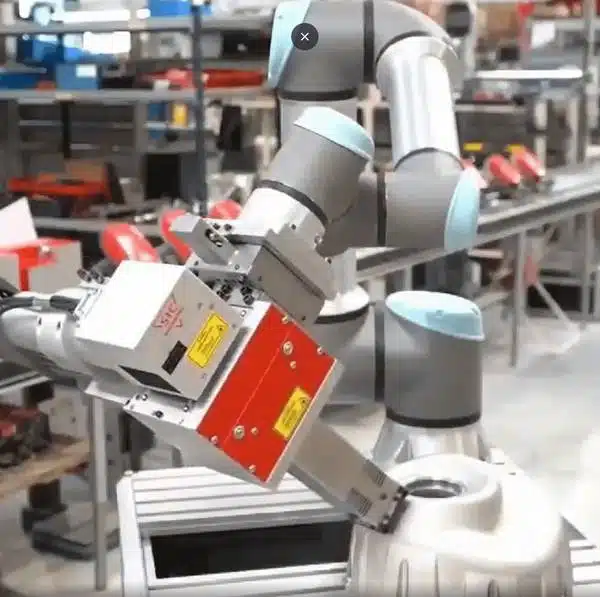

6. Applications:

Automotive parts – Marking crankshafts, engine casings, cam shafts etc.

Medical instruments – Marking surgical instruments for GS1 Datamatrix Compliance

Aerospace components – Marking turbine blades and seal rings

Metal tags/plates – Used for identification of larger machinery or components

Formula 1 – Marking drivetrain components with an annealed finish to not affect surface roughness

7. Considerations:

Requires safety precautions: all of the laser from SIC Marking are Class 1 (Completely safe). There are Class 4 lasers in the market which require specific safety goggles but also need specific risk assessments and management to be used in a safe manner.

Surface preparation may be necessary for certain metals or finishes.

Power, frequency, speed, and focus must be optimized for each material.

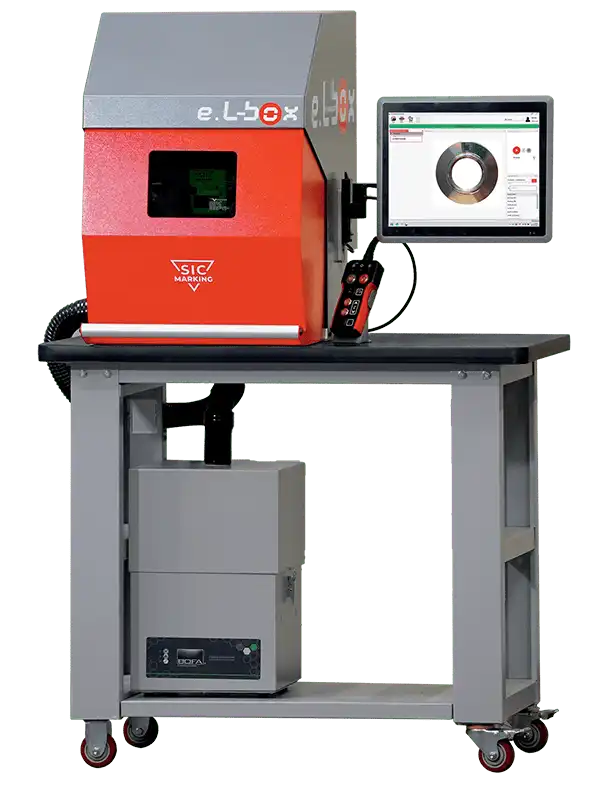

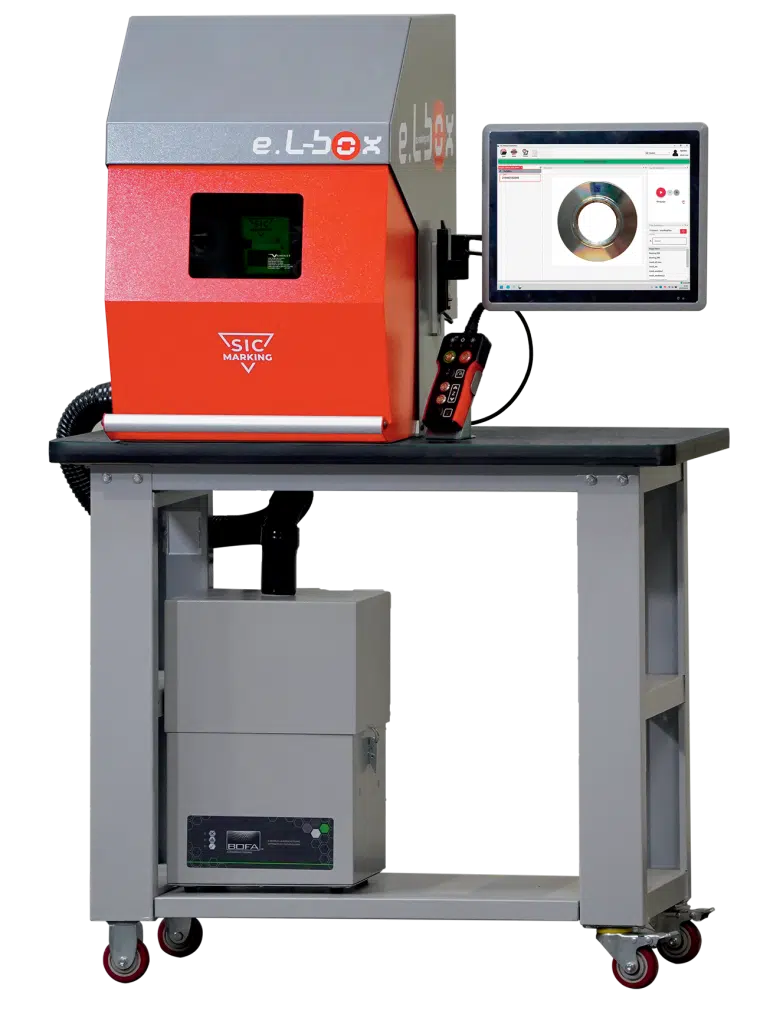

Our product reference

Plug and play – no separate control unit

Precise and high-contrast marking onto a variety of metals and plastics

Rotary axis for full 360 degree marking of cylindrical parts

Take a look at other case studies

Industry

Materials

Technologies

Equipment type

Would you like to know more?

Contact us!