In the industrial sector, it is essential to understand the difference between industrial engraving and deep marking.

While engraving can vary in depth and is often used for aesthetic or informational purposes, deep marking of industrial parts is primarily designed for durability and wear resistance.

Deep engraving stands out for its ability to create markings whose durability far exceeds that of traditional engraving. By frequently reaching a depth greater than 0.2 mm, direct part marking offers excellent resistance to mechanical wear, heat treatments, and even chemical exposure.

Deep marking addresses key industrial challenges such as permanent traceability, resistance to extreme environments, compliance with industry standards, safety and tamper-proof identification, as well as maintenance tracking and lifecycle management of parts.

Thanks to its integration into the material itself, deep direct part marking ensures optimal readability and maximum protection against any falsification or alteration. This level of security is essential in highly demanding industries such as aerospace, railway, or defense.

The marking technologies used for deep engraving often combine multiple methods to achieve the required depth and precision.

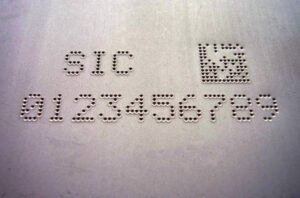

Depending on technical and economic requirements, SIC MARKING offers different deep engraving machines designed to meet the challenges of direct part marking for industrial components.

or call us at +33 (0)4 72 54 80 05

When selecting the right marking technology for deep engraving, manufacturers must carefully assess several technical, environmental, and economic criteria.

It is essential to evaluate the material to be marked, its hardness, and any prior treatments. Certain technologies, such as laser marking or electromagnetic dot peen marking, may face limitations on very hard or heat-treated materials.

By analyzing these factors, manufacturers ensure not only the efficiency and durability of the marking process but also cost optimization and compatibility with their industrial workflow.

All these factors should be evaluated against the production volume and the required marking depth.

Deep scribing is a mechanical technique that creates a durable and precise linear mark on a wide range of materials.

It is particularly valued in demanding industries such as defense, construction equipment, and railway, where resistance to environmental stress and long-term readability are essential.

This method guarantees a silent marking process, without heavy impact, which preserves the part’s integrity while ensuring reliable traceability and protection against tampering.

Fiber laser deep marking is an advanced technology that uses a high-density light beam to engrave with precision and long-term durability on a wide variety of materials.

Laser marking is widely adopted in demanding industries such as defense, aerospace, and railway, where visual quality and marking resistance are critical.

Thanks to its multi-pass process, it achieves an optimal engraving depth without altering the integrity of the part. Manufacturers value its ability to integrate secure, scannable codes that are essential for traceability and compliance with strict industrial standards.

Electromagnetic dot peen deep marking is a precise and durable solution for industrial part identification.

It uses a stylus driven by a magnetic field to create indented marks that are sharp and consistent across different materials, ensuring reliable traceability without damaging the surface.

Contact Us

Need more information?