×

case study

The client wanted to mark a wide variety of meteorological monitoring tools with alphanumeric codes.

Marking extends, for example, from screwdrivers to portable electrical equipment.

The items to be marked not only have different shapes and sizes, but are also made from numerous materials, such as stainless steel, plastic, etc.

In addition, on each batch change and from the perspective of optimising the traceability process, adjustment of the marking system needs to be fast and precise.

SIC MARKING needs to produce a laser station capable of adapting to parts and tools of widely varying types and dimensions, and, irrespective of the material, ensuring high quality professional marking guaranteeing outstanding traceability.

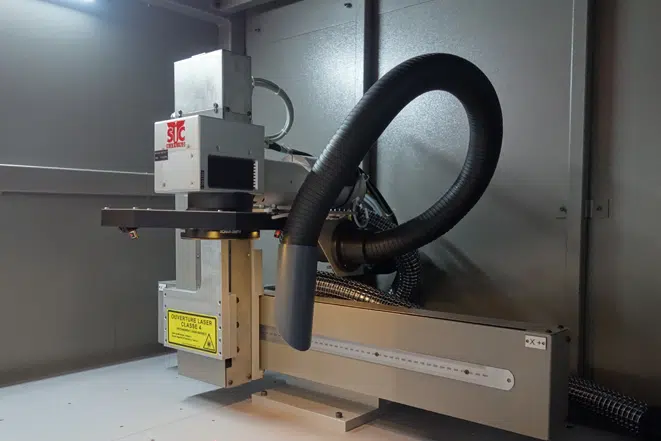

The chosen solution is a 1200 mm XXL-BOX laser marking station, equipped with an EASY 20W laser. To satisfy the client’s requirements,

the X and Z axes are controlled using a joystick situated on the button box.

. As each axis has a stroke of 500 mm, this results in a significant marking volume: 670 mm for the X axis, 250 mm for the Z axis and 170 mm for the Y axis. This condition is important for rapidly moving from one part to another.

This solution perfectly fulfils the client’s requirements in terms of the precision and speed of adjustment, thanks to 1/10 precision and its 2 displacement speeds:

Contact us!