×

case study

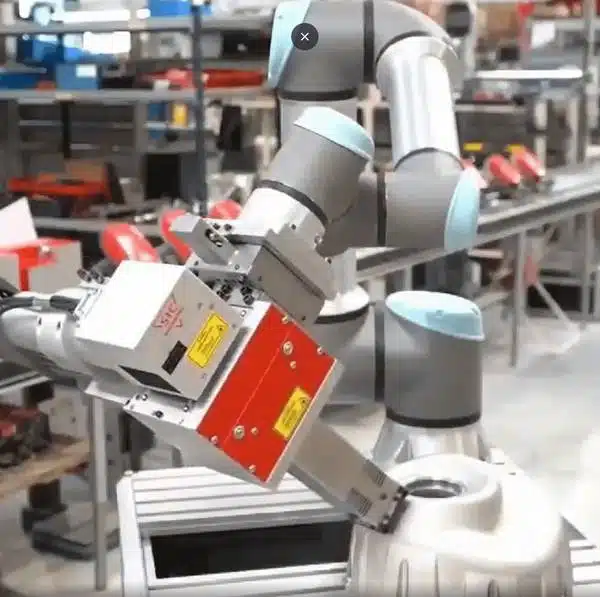

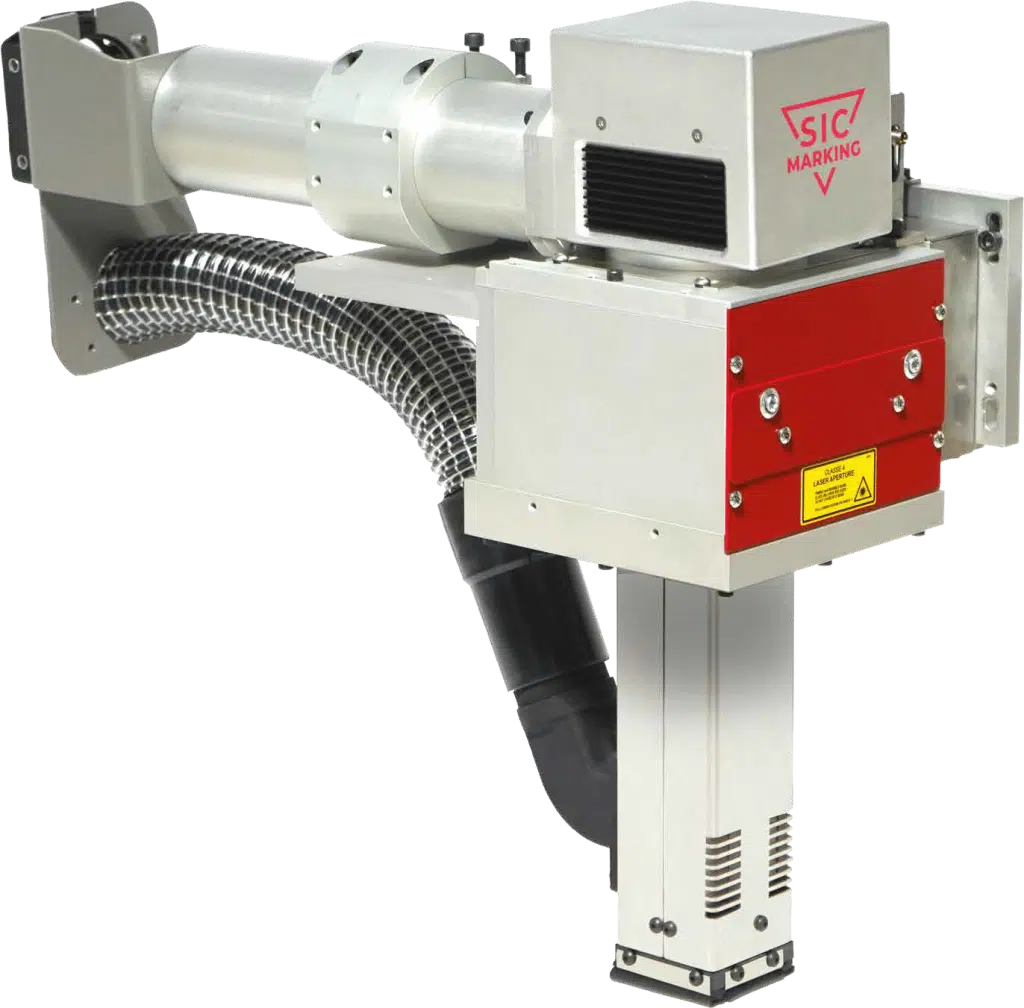

The F.I.T Laser from SIC Marking is a cutting-edge Class 1 ready laser marking machine designed specifically for integration into automated, robotic production environments. Engineered for maximum flexibility and safety, the F.I.T Laser combines robust industrial performance with unparalleled adaptability, enabling manufacturers to meet the highest standards in part traceability, product identification, and industrial automation.

The challenge – Creating a safe but flexible system

Safety is paramount in modern production environments. The F.I.T Laser marking machine is fully enclosed and certified as a Class 1 ready laser marking system, meaning it is completely safe for operators and complies with stringent international laser safety standards. Its compact, sealed design eliminates the need for additional protective enclosures, simplifying integration into your existing robotic production line.

Flexible Mounting Options for Maximum Efficiency

Whether your application requires on-the-fly marking or fixed-station precision, the F.I.T Laser offers the flexibility to suit your process:

The F.I.T Laser is designed for the smart factory. It features easy integration with industrial communication protocols such as Profinet, Ethernet/IP, and Profibus, enabling seamless coordination with PLCs, robotic systems, and MES platforms. It supports real-time data exchange, remote diagnostics, and advanced traceability solutions, making it a powerful tool for Industry 4.0 and smart manufacturing.

With SIC Marking’s proven laser technology, the F.I.T Laser delivers precise, permanent marks on a wide range of materials, including:

Whether you’re marking serial numbers, barcodes, Data Matrix codes or logos, the F.I.T Laser ensures crisp, high-contrast results that are resistant to wear, heat, and corrosion.

Small footprint for easy installation on robot arms or within confined production cells

Modular design allows for customization and scalability

User-friendly interface with SIC Marking software for easy programming and control

This laser marking system is ideal for industries such as automotive, aerospace, electronics, and medical device manufacturing, where space, speed, and precision are crucial.

✅ Class 1 ready laser safety – no need for extra enclosures

✅ Robot arm or static mounting options for ultimate flexibility

✅ Fast, permanent marks on all industrial materials

✅ Easy to integrate with robotic and automated systems

✅ Industry 4.0 ready – smart connectivity and data integration

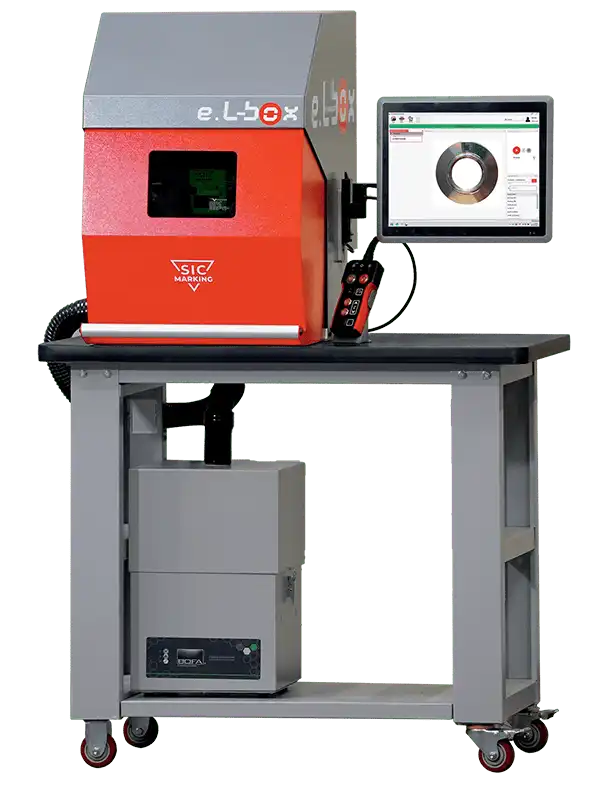

Our product reference

Take a look at other case studies

Industry

Materials

Technologies

Equipment type

Would you like to know more?

Contact us!