×

case study

Our client is a Swiss company specialising in casting.

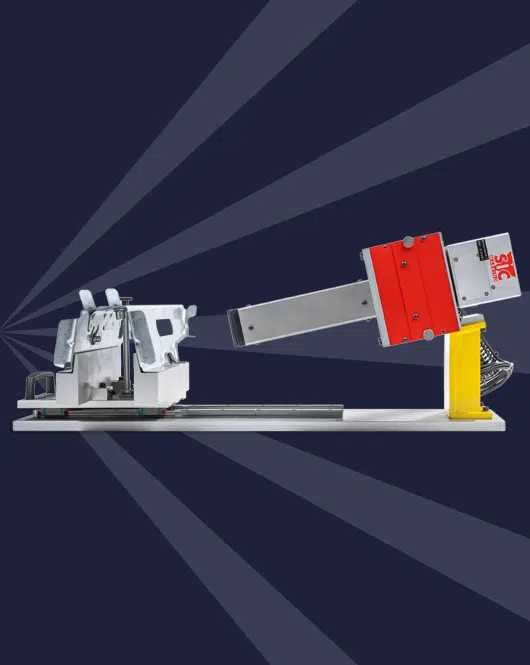

It makes die casting machines for producing aluminium parts.

The managers of the casting company contacted SIC MARKING, as they wanted to be able to provide a marking solution in their casting cells, to identify parts and guarantee their traceability.

The challenge in this case is two-fold:

With years of experience and perfectly harnessed expertise, the SIC MARKING team developed a F.I.T. LASER (standard laser funnel) for this project in order to satisfy all the client’s requirements.

This is a conventional approach for our teams consisting of meeting clients’ marking requirements, as well as taking account of the production environment’s characteristics (heat, dust, humidity level, etc.)

Contact us!